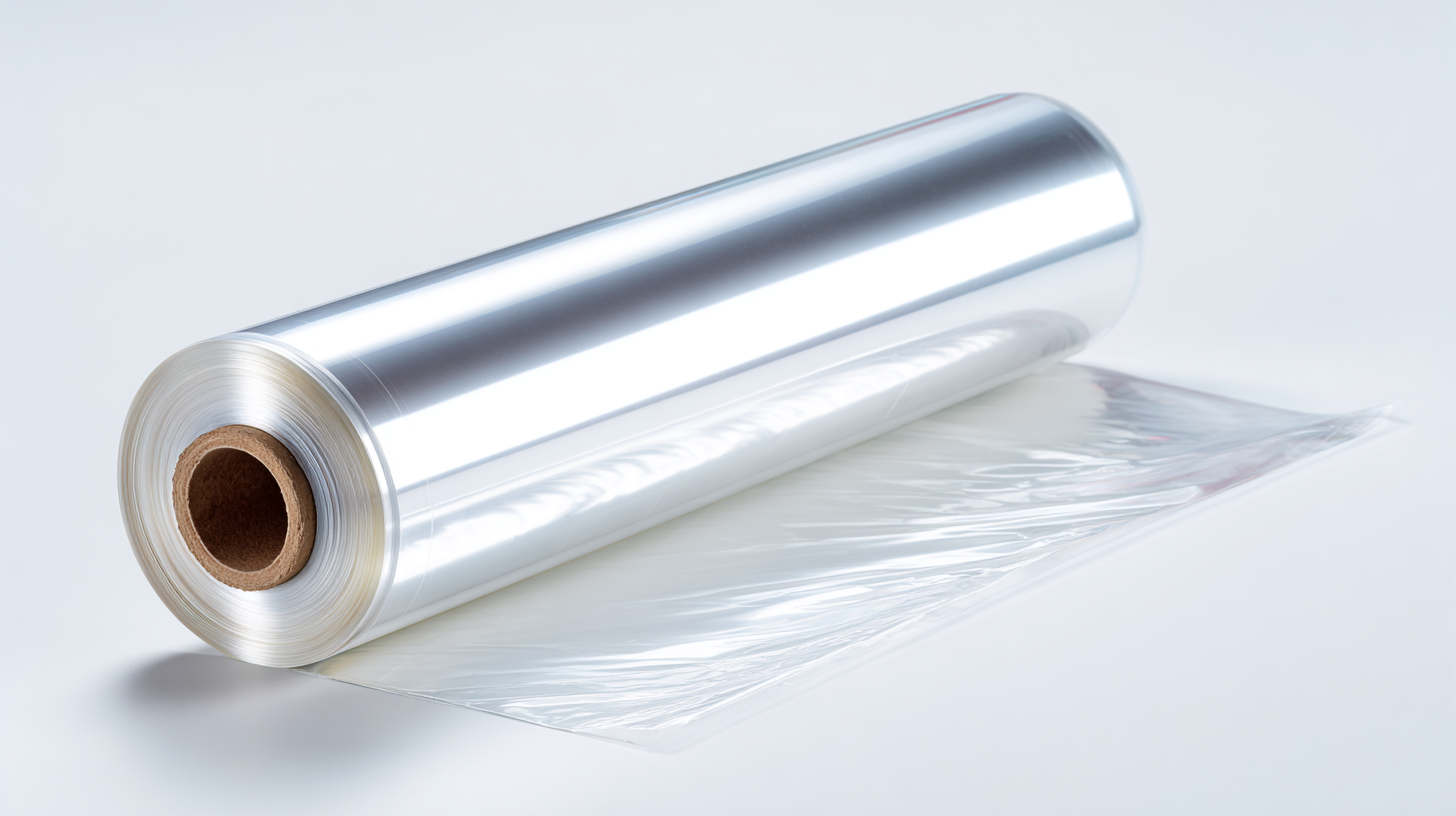

7 Reasons Why Best OPP Single Layer Heat Sealing Film Should Be Your Top Choice

When it comes to packaging solutions, choosing the right materials is crucial to ensure product quality and presentation. One standout option in the market is the OPP Single Layer Heat Sealing Film, a versatile and efficient choice for various applications. This blog aims to explore the seven compelling reasons why this film should be your top choice for heat sealing needs. From its exceptional barrier properties to ease of use and compatibility with multiple surfaces, the OPP Single Layer Heat Sealing Film offers unrivaled benefits that can enhance your packaging process. We will delve into the detailed technical specifications that make it a superior option, alongside practical tips on how to effectively utilize it in your operations. If you’re looking to optimize your packaging solutions, understanding the advantages of this film is essential.

The Significance of OPP Single Layer Heat Sealing Film in Modern Packaging Technology

In the ever-evolving world of packaging technology, OPP (Oriented Polypropylene) single layer heat sealing film has emerged as a significant player. This innovative material offers unparalleled advantages that cater to the dynamic needs of various industries. Its strength and flexibility make it ideal for custom packaging solutions, ensuring products are delivered intact while maintaining an appealing presentation.

The clarity of OPP film also enhances product visibility, making it a preferred choice for brands looking to attract consumers on the shelf.

The clarity of OPP film also enhances product visibility, making it a preferred choice for brands looking to attract consumers on the shelf.

Moreover, the heat sealing capability of OPP film contributes to efficient production processes. It enables faster packaging speeds and reduces the likelihood of leaks or contamination, ensuring that the integrity of the product is preserved. This film is not only cost-effective but also environmentally friendly, as it can be recycled and is made from materials that are less harmful to the ecosystem compared to traditional packaging options.

As businesses increasingly prioritize sustainability alongside efficiency, OPP single layer heat sealing film stands out as a smart investment in modern packaging technology.

Innovative Features of the Best OPP Films for Enhanced Product Protection

When it comes to protecting your products, the choice of packaging materials can make all the difference. The best OPP (Oriented Polypropylene) single-layer heat sealing films stand out due to their innovative features that enhance product protection. One of the key attributes of these films is their exceptional clarity, which not only showcases the product beautifully but also provides a barrier against moisture and contaminants. This ensures that the integrity of the product is maintained throughout its shelf life, making it ideal for food items and other perishable goods.

Additionally, the best OPP films offer remarkable strength and durability. Their resistance to tearing and puncturing means that they can withstand the rigors of transportation and handling, giving businesses confidence that their products will arrive in pristine condition. Moreover, these films are designed for easy heat sealing, which simplifies the packaging process while ensuring a secure closure that further minimizes the risk of contamination. With their advanced features, OPP single-layer heat sealing films represent a smart choice for businesses looking to protect their products effectively while maintaining a high level of visual appeal.

7 Reasons Why Best OPP Single Layer Heat Sealing Film Should Be Your Top Choice

| Feature | Benefit | Application |

|---|---|---|

| High Clarity | Enhances product visibility and appeal | Food packaging, retail items |

| Excellent Heat Sealability | Ensures secure packaging for various products | Snacks, electronics, pharmaceuticals |

| Durable and Tear-Resistant | Protects contents from damage during transport | Shipping, retail displays |

| Moisture Resistance | Preserves freshness and quality of food items | Bakery products, fruits |

| Environmentally Friendly Options | Appeals to eco-conscious consumers | Organic products, sustainable brands |

| Versatile Sizes and Thicknesses | Accommodates different packaging needs | Custom products, various industries |

| Cost-Effective | Reduces overall packaging expenses | Manufacturers, distributors |

Comparative Analysis: OPP vs. Other Heat Sealing Films in 2025

When comparing OPP single layer heat sealing films to other types in 2025, one immediately notices the superior sealing performance and versatility that OPP offers. Unlike PVC or paper-based alternatives, OPP films are known for their excellent clarity and strength, making them ideal for packaging applications where visibility and product protection are crucial. Their resistance to environmental factors, such as moisture and temperature fluctuations, further enhances their appeal, ensuring that your products remain secure and presentable.

Tip: When selecting heat sealing films, consider the specific requirements of your product. OPP films are often preferred for food packaging due to their non-toxic properties and ability to maintain freshness. Always check for certifications that guarantee safety, especially for food-related applications.

Moreover, OPP films require lower sealing temperatures compared to alternatives like PET or LDPE, which can save energy and reduce production costs. This lower sealing temperature not only speeds up the packaging process but also minimizes the risk of damaging heat-sensitive products. Choosing OPP can ultimately lead to a more efficient packaging operation.

Tip: Evaluate the sealing parameters for your packaging line. Adjusting the heat and pressure settings for OPP films can optimize your sealing process, ensuring a reliable seal every time.

How to Choose the Right OPP Single Layer Heat Sealing Film for Your Business Needs

When selecting the right OPP single layer heat sealing film for your business needs, it’s crucial to consider various factors that will ensure optimal performance and efficiency. First, evaluate the specific requirements of your packaging process. Consider the types of products you are sealing, as different materials may require unique sealing properties. A film that is too thick may not provide the necessary flexibility, while one that is too thin may not offer adequate protection for your products.

Another essential tip is to examine the compatibility of the film with your sealing equipment. Not all films work well with every machine, so it’s vital to ensure that your chosen film can be easily processed on your existing systems. Additionally, consider the environmental impact of your choices; look for films that offer improved sustainability options. Many suppliers are now offering OPP films that are recyclable or made from responsibly sourced materials, allowing you to align your packaging with environmentally friendly practices.

Lastly, assess the quality and reliability of your supplier. A trustworthy supplier will provide detailed specifications, test data, and customer service support that can help you make an informed decision. Investigating potential suppliers’ reputations can save you time and effort in the long run, ensuring that you always have access to the best materials for your heat sealing needs.

Future Trends: Sustainability and Efficiency in OPP Heat Sealing Film Production

In an era where sustainability is at the forefront of industry practices, the future of OPP heat sealing films reflects a significant shift towards eco-friendly solutions. Biodegradable polymers are emerging as a viable alternative in packaging, particularly in the food sector, where the risks associated with non-biodegradable materials are becoming increasingly evident. With consumers demanding greener options, OPP films that prioritize sustainability will not only enhance brand reputation but also align with global efforts to reduce landfill waste.

In an era where sustainability is at the forefront of industry practices, the future of OPP heat sealing films reflects a significant shift towards eco-friendly solutions. Biodegradable polymers are emerging as a viable alternative in packaging, particularly in the food sector, where the risks associated with non-biodegradable materials are becoming increasingly evident. With consumers demanding greener options, OPP films that prioritize sustainability will not only enhance brand reputation but also align with global efforts to reduce landfill waste.

Recent advancements in packaging technology highlight a trend towards increased efficiency and reduced environmental impact. Innovations in low-density films, specifically tailored for various applications such as ice cream packaging, showcase the industry's commitment to improving performance while maintaining sustainability standards. Furthermore, as the flexible packaging sector evolves, understanding the intricacies of heat sealing—such as the factors that affect seal integrity—becomes crucial for manufacturers aiming to optimize their processes while adhering to eco-friendly practices. As we look ahead, investing in OPP heat sealing films that embrace these principles will be pivotal for companies striving to succeed in a competitive market.